Minimize your application's downtime or it bring back to performing at its full power.

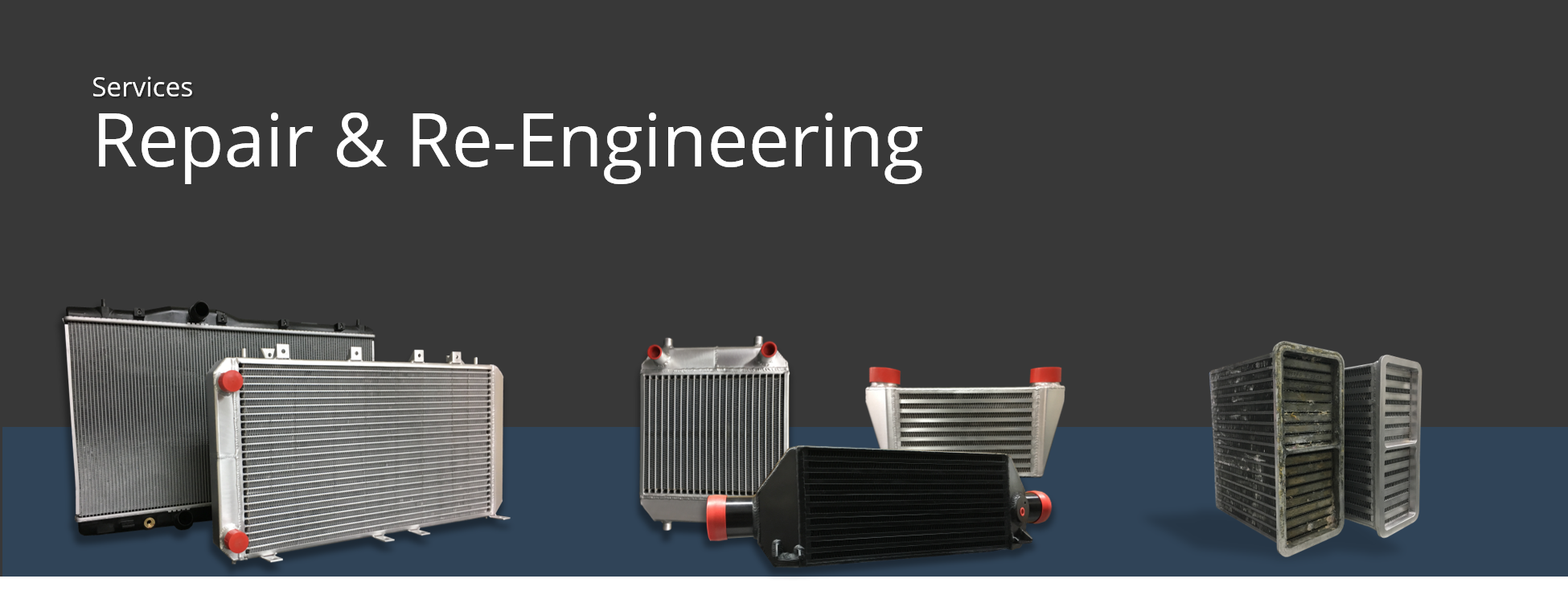

There is a good probability that your Charge Air Cooler / Intercooler, Oil Cooler, Radiator or Charge Air Cooler will be subject to failure in service at some point, over the lifetime of your vehicle, mobile machinery or static equipment. At Bell Intercoolers we can rebuild any type of intercooler, oil cooler or radiator. Your failed cooling system may have a unique configuration or design, which may justify repairing it instead of replacing the complete unit.

If the core in your intercooler, radiator or oil cooler has been damaged by a piece of debris coming through it, or is leaking due to metal fatigue, it needs to be replaced. Epoxy or weld patches will just not work. These will eventually fail, cause even more leaks or bigger problems, wasted money, and significant down time. The right option to repair your intercooler will most often be to re-core it, or exchange the core for a new one.

Replication of Obsolete Parts.

At Bell Intercoolers, we have the experience and technology to reverse-engineer obsolete parts and then re-design them to improve their performance. Heat exchangers are often designed and built on production lines which become obsolete in only a few years. When a replacement heat exchanger cannot be obtained from its original manufacturer, the only way to replace it is to design and build a new one that fits and functions like (or better) than the original one.

When working on reproducing an obsolete part or improving the performance of a customer cooling system, our Re-Engineering process and capabilities enable us to make precise changes that meet specifications with the greatest of accuracy. It also helps us to create products that perform better and last longer.

Re-Engineering Process

By leveraging the use of the latest in design technology, we ensure that every cooling system fits and performs perfectly from the start, without any modifications to your vehicle of equipment.

01.

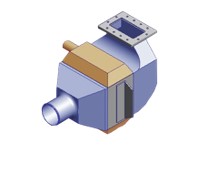

Data Acquisition

Bell Intercoolers uses the latest in laser scanning technology to digitize parts with extreme accuracy and speed.

02.

Digital Modeling

Through the use of Solidworks®, Bell Intercoolers creates precise electronic drawings and accurate 3D models of every cooling system that goes through our re-engineering process.

03.

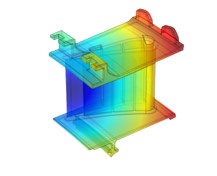

Simulation Analysis

We'll use SolidWorks® 3D Modeling for FEA (Finite Element Analysis) to perform stress tests and simulation analysis to design products that perform according to the requirements of each application.

The right experience and capabilities.

At Bell Intercoolers, we have the experience and capabilities to repair or recondition cooling systems back to their full working capacity. We take advantage of our extensive core inventory to exchange a failed core for a new one, utilizing the existing components in your cooling system, such as tanks, threaded connections, fitting or mounts. With a team of highly experienced and skilled fabricators, Bell Intercoolers can exchange your core, re-assemble your complete cooling system, and restore it back to working conditions in a short time. If the tanks or other components in your cooling system are in bad shape, then your best option may be to replace the entire cooling system with a new one, as this will save you money in the long run. Regardless of your need, you can rely on Bell Intercoolers to extend the usable life of your cooling system for increased value, or to upgrade it for increased performance.

Signs of a damaged or leaking intercooler

- Noticeable drop of the engine power.

- Increased fuel consumption.

- Unnatural smoke from the exhaust system.

- Clogged intercoolers will cause an increase in the temperature of the air flowing into the engine.

Frequent causes of intercooler failure

- Frontal accidents from objects thrown from the road.

- Manifold cracks due to vibration / excess stress loads.

- Tubes clogged by oil, dirt or damaged turbo parts.

- Improper sealing of the turbo unit.

- Soiled surface of the intercooler.